Cenosphere is an exclusive byproduct arising from the combustion of coal and is commonly produced in the course of burning coal within thermal power plants. The combustion of pulverized coal in power plants results in the production of fly ash. Within this fly ash, cenospheres are the lighter particles. Comprising hollow, lightweight particles composed of silica, alumina, and iron oxide; these spheres are excellent lightweight fillers that exhibit intriguing characteristics that make them highly beneficial across various industrial uses.

Noteworthy attributes include elevated crush strength, resistance to pressure, superb thermal insulation properties, and a non-toxic, non-hazardous nature. Their distinctive particle shape facilitates convenient application and imparts a polished finish. The Cenosphere means "hollow spheres" and is derived from the two Greek words Kenos and Sphaera. Durgesh Group is a leading manufacturer, supplier, and exporter of extremely lightweight and free-flowing Cenospheres in India.

Production of Cenosphere in India

The combustion of coal in thermal power plants in India results in the production of fly ash, which predominantly contains ceramic particles, composed of alumina and silica. These particles are formed at temperatures ranging from 1,500 to 1,750 °C through intricate chemical and physical transformations. The chemical composition and structure of these ceramic particles vary significantly based on the coal composition that gave rise to them. There are three types of structures for the ceramic particles in fly ash. The first type consists of solid particles known as precipitators. The second type comprises hollow particles called cenospheres. The third type is referred to as plerospheres, which are large-diameter hollow particles filled with smaller precipitators and cenospheres. This diverse range of structures characterizes the complex manufacturing of these particles in India.

Characteristics of Cenosphere

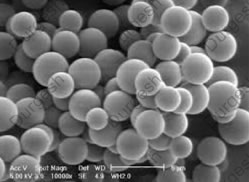

Cenospheres are ceramic microspheres characterized by their hollow structure, containing negatively pressurized gas composed of nitrogen and carbon dioxide. These microspheres exhibit exceptional qualities such as:

- Extremely lightweight

- Low density

- High compression strength

- High melting point

- High electrical resistance

- Low coefficient of heat conduction and thermal contraction

- High abrasion resistance

In the contemporary landscape, Cenospheres stands out as the world's leading lightweight high-performance filler material, surpassing other mineral fillers across various industries. Its utilization not only reduces the cost and weight of products but also enhances multiple performance aspects of the filled items. Consequently, Cenospheres play a pivotal role in diverse applications, contributing significantly to enterprises by creating substantial economic benefits.

Chemical Properties of Cenosphere

Cenospheres, hollow ceramic microspheres, boast distinctive chemical properties. Comprising silica, alumina, and iron oxide, their composition varies with coal sources. These spheres exhibit nitrogen and carbon dioxide-filled negative pressurized gas, endowing them with unique features. Cenospheres are characterized by low density, high compression strength, a high melting point, elevated electrical resistance, low coefficients of heat conduction and thermal contraction, and notable abrasion resistance.

The color of Cenospheres varies from gray to almost white and their density is about 0.4–0.8 g/cm3 (0.014–0.029 lb/cu in), which gives them a great buoyancy. Their chemical makeup, determined by the coal they originate from, influences these properties, making cenospheres valuable for diverse applications. In industries, they play a crucial role, offering economic benefits through their exceptional chemical attributes.

Advantages of Using Cenospheres

While cenospheres originate from fossil fuel resources, they serve as an environmentally friendly chemical feedstock with significant utility. Being a lightweight filler and due to numerous advantages, cenospheres are used in diverse industrial applications. Some of the major advantages of using cenospheres in diverse sectors include:

- Cenospheres are 75% lighter than other minerals currently used as a filler or extender and are 30 percent lighter than most resins.

- These lightweight, hollow ceramic microspheres offer enhanced mechanical strength, contributing to materials with reduced density.

- The spherical shape of cenospheres improves flowability in most applications and provides a more even distribution of the filler material.

- Their small size and high melting temperature make them versatile additives for various products, providing benefits such as improved durability and heat resistance.

- Cenospheres excel as thermal insulators, offering energy efficiency in coatings and paints.

- The natural properties of Cenospheres make it possible to use them either in dry or wet slurry form.

- Moreover, their use imparts corrosion resistance, extending the lifespan of coated materials.

- These microspheres are also multifunctional binders for thermosetting and thermoplastic materials, adding versatility to their applications.

- Cenospheres are easy to handle and provide a low surface area-to-volume ratio. Due to their inert properties, they are not affected by solvents, water, acids, or alkalis.

- Utilization of Cenospheres reduces the cost of manufacturers' raw materials. The savings may be recognized in one or more of the benefits like reduced raw materials, improved insulation values, resistance to resin absorption, and low weight of the end product.

Overall, the advantages of employing cenospheres include reduced weight, improved mechanical properties, thermal insulation, and corrosion resistance, making them valuable components in diverse industrial processes.

Application of Cenospheres

Cenospheres, with their unique properties, find diverse applications across various industries. Their mechanical strength, small size, low density, high melting temperature, and thermal insulating properties make them valuable. Particularly, cenospheres excel in providing thermal insulation to coatings or paints, enhancing corrosion resistance.

These versatile microspheres serve multiple functions, functioning as binders for both thermosetting and thermoplastic materials. In summary, the uses of cenospheres in various industries encompass thermal insulation, corrosion resistance in coatings, and their role as multifunctional binders for thermosetting and thermoplastic applications.

- Cenospheres in the Oilfield: Cenospheres play a crucial role in the Oil and gas Industry, serving as additives during drilling operations for boreholes, wells, and offshore locations for oil extraction. Properly incorporated, cenospheres can enhance drilling strength and intensity by up to 50%. Additionally, they find application in plugging oil and gas wells and filling expansions around the wellbore. In the construction of oil tanks, cenospheres are blended with cement solutions to create a robust material, offering stability and heat-insulating properties.

- Cenospheres in Oil Well Cementing: Cenospheres, with a particle size of 500 microns, play a crucial role in oil well cementing. These lightweight, hollow microspheres enhance the cement slurry's properties, improving its density and reducing overall weight. This is particularly beneficial in oil well applications, where the right balance is essential to prevent formation damage and ensure well integrity. Cenospheres contribute to cement's compressive strength, minimize fluid migration, and enhance thermal insulation. Their use in oil well cementing helps optimize the cement formulation, ensuring reliable and efficient wellbore integrity while meeting the stringent demands of the oil and gas industry.

- Cenospheres in Plastics and Polymers: Cenospheres play a vital role in the manufacturing of plastics and polymers, serving as widely utilized components. These microspheres contribute to reshaping plastics, leveraging their strength and minimal shrinkage properties. In recent developments, cenospheres have found application as a sheet molding compound, proving to be a cost-effective alternative to previously employed materials like aluminum and calcium carbonate in-vehicle applications.

- Cenospheres in Construction: Cenospheres find extensive application in the construction industry, with ongoing developments leading to the creation of new products and applications. Whether in roofing materials, stuccos, or grouts, the versatility of cenospheres contributes to their widespread use. The construction sector is witnessing a continuous increase in the incorporation of cenospheres, as an expanding number of companies recognize the advantages that these microspheres bring to their products. This ongoing growth underscores the valuable role cenospheres play in enhancing various construction materials and processes.

- Cenospheres in Automobiles: Cenospheres play a crucial role in the automobile industry, primarily as lightweight fillers in materials used for vehicle components. Their low density and high strength properties make them valuable additives in applications such as automotive plastics, composites, and coatings. Cenospheres contribute to weight reduction, improving fuel efficiency and overall vehicle performance. Additionally, they find use in soundproofing and thermal insulation applications, enhancing the comfort and efficiency of automobiles.

State-of-the-art Cenospheres Production Plant

Since 2003, Durgesh Group, situated in Giridih, Jharkhand, India has been a leading processor and exporter of cenospheres. Our cutting-edge, fully automated plant spans 5 acres, featuring over 50,000 square feet for finished product storage and 100,000 square feet for raw materials. The entire process, from raw material intake to final product discharge into jumbo bags, is seamlessly automated.

With an annual capacity exceeding 3,000 metric tons, our plant is designed using global techniques to produce India's most lightweight cenospheres. Operated under stringent HSE and QAQC standards, our facility complies with global norms and has gained approval from numerous Fortune 500 companies, solidifying our status as the "Best Processing Facility of Cenospheres in India." Our clientele spans the USA, Middle East, North Africa, Japan, South-East Asia, Europe, and South America.

Why Choose Us for Cenospheres?

Durgesh Group is a prudent choice for procuring cenospheres due to its exceptional commitment to quality, reliability, and innovation. With a solid reputation in the industry, Durgesh Group ensures a consistent supply of high-quality cenospheres with a particle size of 500 microns, ideal for oil well cementing. Their state-of-the-art production facilities adhere to rigorous quality control standards, guaranteeing product excellence. Durgesh Group's dedication to research and development ensures that their cenospheres meet or exceed industry specifications, providing optimal performance in myriad applications. Additionally, their customer-centric approach, timely delivery, and competitive pricing make us a preferred partner, offering comprehensive solutions for the unique requirements of diverse sectors. Some of the prominent reasons that make Durgesh Group a pioneer in the field include:

- Best in the Industry Reputation.

- Over 30 years of experience.

- An ISO 9001:2000 certified company.

- Automatic Production Plant.

- Committed to honesty, transparency, and ethical business practices.

Cenospheres FAQs

Where are cenospheres typically found in nature?

Cenospheres are not naturally occurring in the environment but are instead a byproduct of industrial processes, specifically the combustion of coal in thermal power plants. After coal is burned, cenospheres are formed as hollow, lightweight particles that float on the surface of molten ash. They are collected from the ash ponds or fly ash collection systems of power plants and are not found naturally in geological formations.

What is the primary use of cenospheres in industrial applications?

Cenospheres, lightweight hollow spheres primarily composed of silica and alumina, find diverse industrial applications. They're utilized as fillers in various materials like plastics, cement, and composites, enhancing strength and reducing weight. In construction, they improve concrete's properties, enhancing insulation and reducing density. Additionally, they're employed in coatings, adhesives, and even in the automotive industry to enhance properties like thermal insulation and soundproofing.

How do cenospheres contribute to lightweight materials?

Cenospheres, lightweight hollow spheres derived from fly ash, contribute to lightweight materials by displacing heavier components without compromising structural integrity. Their low density and high strength-to-weight ratio make them ideal fillers in composites, plastics, and cement. By incorporating cenospheres, materials become lighter yet maintain or even improve mechanical properties, such as stiffness and durability. This enables the production of lightweight products that offer advantages like reduced fuel consumption, increased payload capacity, and improved thermal insulation.

Can cenospheres be recycled, and if so, how?

Yes, cenospheres can be recycled into cementitious materials to produce lightweight materials. Cenospheres manufacturers recycle them by separating them from fly ash using techniques like flotation, centrifugation, or sieving. Once separated, they undergo cleaning processes to remove impurities. They can then be reused as fillers in various applications, reducing the need for virgin materials and minimizing environmental impact. Recycling cenospheres conserves resources, reduces waste, and offers economic benefits by providing a sustainable alternative to virgin materials.

What is the difference between cenospheres and other lightweight fillers like microspheres?

Cenospheres and microspheres are both lightweight fillers but differ in composition and properties. Cenospheres are hollow spheres primarily composed of silica and alumina, derived from fly ash. Microspheres, on the other hand, can be solid or hollow and are typically made of materials like glass, polymer, or metal. While cenospheres offer high strength-to-weight ratios and thermal insulation, microspheres provide tailored properties such as density, buoyancy, and chemical resistance.

How do cenospheres impact the thermal conductivity of materials?

Cenospheres significantly impact the thermal conductivity of materials by reducing it. As lightweight, hollow spheres with low thermal conductivity, they act as insulating fillers when incorporated into materials like composites or cement. Cenospheres create barriers that impede the transfer of heat, resulting in improved thermal insulation properties. This enables the production of materials with lower thermal conductivity, which can be beneficial for applications requiring thermal insulation, such as construction and automotive industries.

In which industries are cenospheres commonly used?

Cenospheres find widespread use across various industries. In construction, they enhance the properties of concrete, reducing density and improving insulation. They're also utilized in automotive applications for soundproofing and reducing weight. Additionally, cenospheres are incorporated into coatings and paints to improve performance. Their versatility extends to aerospace, plastics, ceramics, and oil drilling industries, where they contribute to lightweight materials, thermal insulation, and improved mechanical properties, among other benefits.

What is the colour and appearance of cenospheres?

Cenospheres typically appear as small, lightweight spheres with a smooth surface texture. They range in colour from white to light grey, depending on factors such as the composition of the fly ash from which they are derived and any processing they may undergo. Their uniform spherical shape and neutral colour make them visually distinctive and suitable for various industrial applications as fillers or additives in materials.

How do cenospheres affect the strength and durability of materials?

Cenospheres enhance the strength and durability of materials by reinforcing their structure without significantly increasing weight. As fillers, they distribute stress more evenly throughout the material matrix, improving resistance to mechanical forces like compression and flexion. Additionally, their inert nature and resistance to chemical degradation contribute to the durability of materials. By reducing density while maintaining or improving mechanical properties, cenospheres enhance the overall performance and lifespan of materials in various applications.

Are cenospheres environmentally friendly?

Cenospheres offer several environmental benefits. They are derived from fly ash, a byproduct of coal combustion, which reduces waste and promotes recycling. Additionally, their use of lightweight materials can contribute to energy savings during transportation and operation. Furthermore, by replacing heavier materials with cenospheres, products become more resource-efficient and may reduce carbon emissions over their lifecycle. However, considerations such as extraction methods and potential pollutants in fly ash should be addressed for comprehensive environmental assessment.

What role do cenospheres play in the production of concrete?

In concrete production, cenospheres serve as lightweight fillers, enhancing various properties. They improve workability by reducing density, allowing for easier placement and finishing. Additionally, cenospheres enhance insulation properties, making concrete more energy-efficient. Their spherical shape also helps to reduce water absorption and shrinkage, improving durability. Furthermore, cenospheres contribute to the reduction of overall material costs while maintaining or even enhancing mechanical strength, making concrete production more economical and sustainable.

Can cenospheres be used in the production of ceramics?

Yes, cenospheres may be used in the production of ceramics. They are incorporated into ceramic formulations to enhance properties such as thermal insulation, mechanical strength, and dimensional stability. Cenospheres act as lightweight fillers, reducing the density of ceramic materials while maintaining or even improving their structural integrity. This makes them suitable for applications where lightweight, durable ceramics are required, such as in aerospace components, refractory linings, and thermal insulation materials.

How do cenospheres influence the density of materials?

Cenospheres significantly influence the density of materials by reducing it. As lightweight hollow spheres, they displace heavier components within a material matrix without sacrificing structural integrity. By incorporating cenospheres, the overall density of the material decreases while maintaining or even improving mechanical properties. This makes them ideal fillers for applications requiring lightweight materials, such as composites, plastics, and construction materials, where reduced density offers advantages like improved fuel efficiency and increased payload capacity.

What are the advantages of incorporating cenospheres into polymer composites?

Incorporating cenospheres into polymer composites offers several advantages. Cenospheres act as lightweight fillers, reducing the density of the composite while maintaining or even improving mechanical properties such as strength and stiffness. They also enhance thermal and acoustic insulation properties. Additionally, cenospheres can decrease material costs by replacing more expensive fillers or polymers. Overall, their incorporation into polymer composites results in lighter, stronger, and more cost-effective materials suitable for various applications.

How are cenospheres extracted from fly ash?

Cenosphere manufacturers extract them from fly ash through a process called flotation. In this method, fly ash is mixed with water and a frothing agent, and then aerated to create bubbles. The cenospheres, being hollow and buoyant, rise to the surface and are collected, while heavier particles sink. After separation, the collected cenospheres undergo washing and drying to remove impurities, resulting in purified cenospheres ready for use in various industrial applications.

How do cenospheres contribute to the creation of green materials?

Cenospheres, hollow microscopic spheres extracted from coal ash, enhance the sustainability of materials. When incorporated into composites like concrete, plastics, or ceramics, they reduce overall density without sacrificing strength, thus promoting lightweight construction. This lowers transportation emissions and energy consumption during production. Additionally, cenospheres' abundance as a waste byproduct makes their utilization environmentally friendly, reducing reliance on virgin materials. Their incorporation into green materials fosters resource efficiency and minimizes environmental impact in various industries.

Are there any life cycle assessments (LCAs) available for products containing cenospheres?

Yes, several life cycle assessments (LCAs) have been conducted for products incorporating cenospheres. These assessments evaluate the environmental impacts of cenosphere-containing materials throughout their entire life cycle, from raw material extraction to disposal. LCAs consider factors such as energy consumption, greenhouse gas emissions, and resource depletion. Results indicate that cenosphere-based products generally exhibit lower environmental footprints compared to traditional alternatives, highlighting their potential contribution to sustainable development and guiding further improvements in manufacturing processes.

How do cenospheres align with circular economy principles?

Cenospheres align with circular economy principles by facilitating resource efficiency and waste minimization. As a waste byproduct of coal combustion, cenospheres offer a sustainable alternative to virgin materials. Incorporating them into various products extends their lifecycle, reducing the need for new resources. Additionally, cenosphere utilization diverts waste from landfills, promoting a closed-loop system where materials are continually reused, recycled, or repurposed. This integration of cenospheres exemplifies the circular economy's goal of preserving resources, reducing waste, and fostering sustainable production practices.

What is the potential for cenospheres in renewable energy applications?

Cenospheres hold potential in renewable energy applications, particularly in thermal insulation for solar panels and wind turbines. Their low thermal conductivity and lightweight properties make them ideal for enhancing energy efficiency and reducing weight in these systems. Additionally, cenospheres could be utilized in energy storage technologies like battery separators, improving performance and safety. Their widespread availability and cost-effectiveness further underscore their promising role in advancing renewable energy solutions.

How can the use of cenospheres in industry contribute to achieving sustainability goals?

The use of cenospheres in industry contributes to sustainability goals by reducing reliance on virgin materials, minimizing waste generation, and lowering energy consumption. Incorporating cenospheres into various products such as concrete, plastics, and ceramics reduces overall environmental impact by decreasing resource extraction and emissions. Additionally, their lightweight nature enables more efficient transportation and construction practices. Overall, cenospheres promote resource efficiency and environmental stewardship across multiple industrial sectors.

Which countries are leading in cenosphere production and why?

India and China are among the leading producers of cenospheres due to their significant coal-fired power generation capacity. Both countries produce large volumes of coal ash, from which cenospheres are extracted. The abundance of coal-fired power plants provides a readily available source of raw material. Additionally, favorable economic factors such as low labour costs and advanced extraction technologies contribute to their dominance in cenosphere production.

How are cenospheres tested for quality and performance?

Cenospheres are tested for quality and performance through various methods. Physical properties such as particle size distribution, density, and shape are analyzed using techniques like microscopy and sieve analysis. Chemical composition is assessed through elemental analysis and spectroscopy. Mechanical properties, including compressive strength and abrasion resistance, are evaluated through standardized testing procedures. Additionally, cenospheres undergo performance testing in specific applications, such as concrete or coatings, to ensure they meet the required specifications for strength, durability, and functionality.

What is the significance of the hollow structure of cenospheres in materials science?

The hollow structure of cenospheres holds significant importance in materials science due to its unique properties. These microscopic spheres offer lightweight reinforcement in composite materials while reducing density. Their hollow structure provides thermal insulation, making them ideal for applications requiring heat resistance. Additionally, cenospheres' low density and high compressive strength contribute to improved performance in various products, including concrete, plastics, and coatings. Their versatility and structural advantages make cenospheres valuable additives in material engineering for achieving desired properties and performance.

How do cenospheres interact with polymers and resins in composite materials?

Cenospheres interact with polymers and resins in composite materials by enhancing mechanical properties and reducing density. When incorporated into polymer matrices, cenospheres act as filler materials, reinforcing the structure and improving strength, stiffness, and impact resistance. Additionally, their low density contributes to lightweight without sacrificing performance. The spherical shape of cenospheres also promotes uniform dispersion within the polymer matrix, ensuring homogeneity and enhancing overall material properties, making them valuable additives in composite material formulations.

How do the electrical properties of cenospheres influence their use in electronics?

The electrical properties of cenospheres, such as their high electrical resistivity and low dielectric constant, make them valuable in electronics. When incorporated into electronic materials and components, cenospheres provide insulation, preventing electrical conductivity and reducing signal interference. Their lightweight and inert nature also makes them ideal as filler materials in electronic packaging, where they help to maintain mechanical integrity while minimizing weight. Overall, cenospheres contribute to improving the performance and reliability of electronic devices and systems.

How might changes in coal usage impact cenosphere availability?

Changes in coal usage, such as a shift towards cleaner energy sources or stricter environmental regulations, could impact cenosphere availability. Reductions in coal-fired power generation may decrease the volume of coal ash produced, limiting the source material for cenosphere extraction. Conversely, increased adoption of technologies for ash utilization or carbon capture may alter the composition of coal ash, affecting cenosphere quality or quantity. Overall, shifts in coal usage patterns may influence the availability and characteristics of cenospheres.

How are cenospheres stored and transported safely?

Cenospheres are typically stored and transported in bulk quantities using sealed containers or bags to prevent moisture absorption and contamination. Adequate ventilation and temperature control are crucial to avoid spontaneous combustion, as cenospheres can be combustible when exposed to certain conditions. Additionally, proper labeling with handling instructions and safety precautions is essential. During transportation, secure packaging and appropriate handling procedures ensure protection against damage or spills, minimizing potential hazards and ensuring safe delivery to end-users.

Are there any certification standards for cenosphere quality?

Currently, there are no specific certification standards exclusively for cenosphere quality. However, cenosphere producers often adhere to general quality management systems such as ISO 9001 to ensure consistent product quality. Additionally, some industries may require compliance with relevant standards for specific applications, such as ASTM International standards for construction materials. While there is no dedicated certification, adherence to industry best practices and customer specifications ensures cenospheres meet quality requirements for various applications.

What are the latest advancements in cenosphere technology?

The latest advancements in cenosphere technology focus on improving their properties and expanding their applications. Researchers are discovering methods to enhance cenosphere surface modification for better compatibility with various matrices and improved dispersion. Additionally, efforts are underway to optimize extraction techniques to increase yield and purity while reducing environmental impact. Furthermore, innovative uses of cenospheres in emerging fields such as nanotechnology and biomedical engineering are being investigated, opening up new avenues for their utilization.

How are researchers improving the extraction efficiency of cenospheres?

Researchers are improving cenosphere extraction efficiency through various methods. One approach involves optimizing the coal combustion process to produce ash with higher cenosphere content. Advanced separation techniques such as centrifugation, flotation, and electrostatic separation are being explored to isolate cenospheres more effectively from coal ash. Additionally, researchers are investigating the use of chemical treatments and surface modification techniques to enhance cenosphere recovery and purity, leading to higher extraction yields and improved overall efficiency in the production process.

How is the quality of cenospheres being enhanced for specific applications?

The quality of cenospheres for specific applications is being enhanced through targeted processing and surface modification techniques. Researchers are tailoring extraction methods to produce cenospheres with desired properties such as particle size, shape, and chemical composition. Surface treatments such as coating or functionalization are applied to improve compatibility with specific matrices or enhance desired characteristics like dispersion and adhesion. These advancements enable the customization of cenospheres to meet the performance requirements of various industries, from construction to aerospace.

How do cenospheres contribute to the economy of coal-using countries?

Cenospheres contribute to the economy of coal-using countries by adding value to coal combustion byproducts. Extracting and processing cenospheres creates employment opportunities and stimulates economic growth in regions with significant coal production. Additionally, selling cenospheres as a raw material for various industries generates revenue and foreign exchange. Moreover, utilizing cenospheres in manufacturing sectors enhances product competitiveness and innovation, fostering economic development. Overall, cenospheres play a vital role in diversifying and bolstering the economies of coal-dependent nations.

What role do cenospheres play in waste management strategies?

Cenospheres play a significant role in waste management strategies by providing a sustainable solution for coal combustion byproducts. As a waste product of coal-fired power plants, cenospheres are typically disposed of in landfills, contributing to environmental concerns. However, their lightweight and inert properties make them suitable for reuse in various industries, reducing the volume of waste sent to landfills. By repurposing cenospheres as valuable raw materials, waste management strategies can be optimized to minimize environmental impact and promote resource efficiency.

Why are cenospheres used in refractory products?

Cenospheres are used in refractory products due to their unique properties that enhance the performance of these materials. Their high melting point and thermal stability make them excellent thermal insulators, reducing heat transfer and improving the refractoriness of the product. Additionally, cenospheres' lightweight nature helps to decrease the overall density of refractory materials without compromising their mechanical strength. This makes them ideal additives for applications requiring heat resistance, such as furnace linings, kiln furniture, and insulation materials in high-temperature industries.

How do cenospheres improve the properties of cement and concrete?

Cenospheres improve cement and concrete properties by reducing density without compromising strength, enhancing workability, and providing thermal insulation. Their lightweight nature decreases the overall weight of structures, while their spherical shape improves flowability during mixing. Additionally, cenospheres mitigate concrete shrinkage, reducing cracking and enhancing durability. By utilizing a waste byproduct, cenospheres also promote sustainability in construction, making them valuable additives for improving concrete performance.

Are there any synthetic methods to produce cenospheres?

While cenospheres are naturally occurring, researchers have developed synthetic methods to produce similar hollow microspheres for specific applications. One approach involves the controlled combustion of organic or inorganic precursors, followed by selective extraction or decomposition processes to create hollow structures. Other techniques include emulsion polymerization and template-based synthesis, where sacrificial templates are used to create the desired hollow morphology. These synthetic methods offer tailored properties for diverse industrial applications.

What factors affect the yield of cenospheres in coal combustion?

Several factors influence the yield of cenospheres in coal combustion, including coal composition, combustion temperature, residence time, and combustion conditions. Additionally, factors such as coal particle size distribution, ash content, and combustion efficiency play significant roles. Optimizing these parameters can enhance cenosphere yield by promoting the formation and retention of hollow microspheres during the combustion process.

How do the properties of cenospheres vary with their composition?

The properties of cenospheres vary depending on their composition, which is influenced by the source material and combustion conditions. Cenospheres composed of different types of coal or combustion residues exhibit variations in density, particle size distribution, chemical composition, and thermal stability. Additionally, variations in composition can affect properties such as compressive strength, thermal insulation, and electrical conductivity. Understanding these variations is crucial for tailoring cenospheres to specific applications in industries such as construction, automotive, and aerospace.